A Key Defense for Safeguarding Dialysis Patients’ Health

With the continuous increase in the incidence of chronic kidney disease, hemodialysis has become a crucial treatment for maintaining the lives of numerous end-stage kidney disease patients. As a fundamental guarantee for dialysis treatment, the quality of dialysis water directly impacts patients’ treatment outcomes and life health, highlighting the critical value of hemodialysis water treatment equipment. Among the many technical solutions to ensure dialysis water safety, thermal disinfection technology has increasingly become an important breakthrough for the industry to enhance equipment performance and optimize water quality management due to its significant advantages.

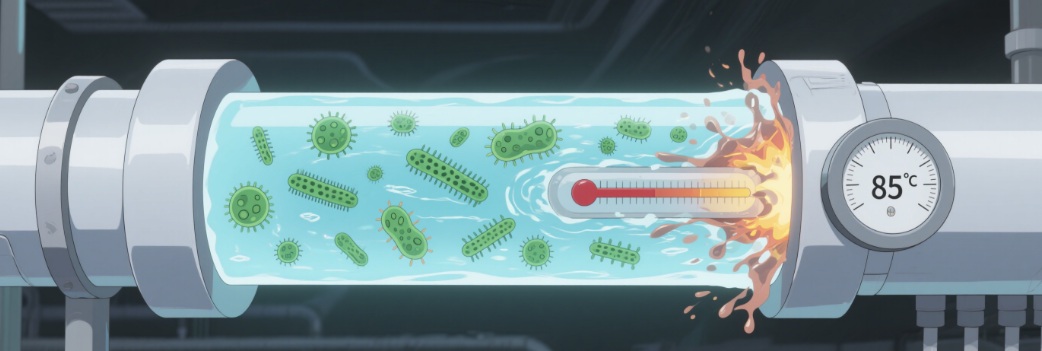

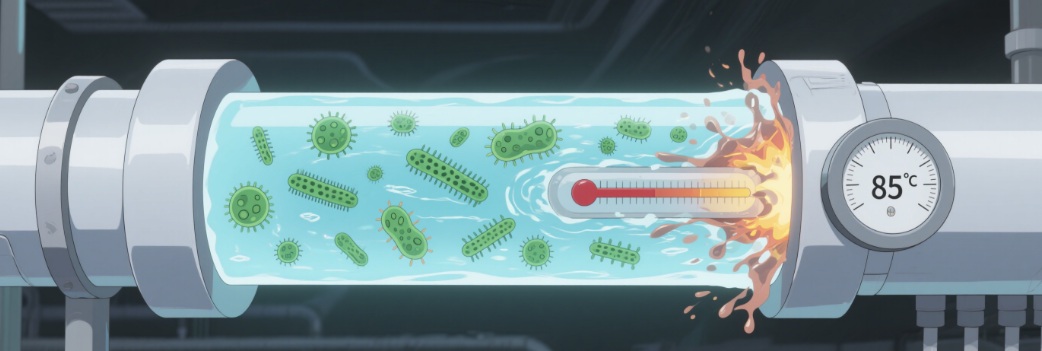

Dialysis water is prone to microbial contamination, commonly by Gram-negative bacilli. These microorganisms can enter the patient’s body during dialysis, potentially causing serious complications such as sepsis and endotoxemia. Studies have shown that the levels of bacteria and endotoxins in dialysis water are closely related to the regular disinfection of reverse osmosis machines and pipelines. Without regular disinfection, microorganisms can form biofilms on the equipment’s surface. This biofilm structure not only provides a protective barrier for microorganisms but also promotes their rapid reproduction, leading to significant increases in bacterial and endotoxin levels. Therefore, strictly controlling the quality of dialysis water is a key link in preventing bacterial pyrogen contamination and ensuring the safety of patients’ dialysis treatment. The thermal disinfection function of hemodialysis water treatment equipment raises the water temperature within a short time and continuously circulates and flushes it through the equipment’s pipelines and related systems for 20-30 minutes. High temperatures cause irreversible damage to key substances such as proteins and nucleic acids in microorganisms, rendering them inactive.

Traditional chemical disinfection methods, such as using sodium hypochlorite and peracetic acid, can achieve disinfection but suffer from the problem of disinfectant residues. These residual chemical substances can enter the patient’s bloodstream, potentially causing allergic reactions, irritating blood vessels, and, with long-term accumulation, may damage organs such as the liver and kidneys. Additionally, they have the drawbacks of long time consumption and high reverse osmosis water usage. In contrast, thermal disinfection is developed based on the principle of pasteurization. It does not rely on any chemical agents, can be used frequently, and has no toxic substance residues, fundamentally eliminating the potential threats of chemical residues to patients’ health. Especially for dialysis patients with fragile physical functions and low immunity, the thermal disinfection function further strengthens the safety barrier for their dialysis treatment environment.

During the long-term operation of hemodialysis water treatment equipment, impurities and microorganisms in the water easily adhere to the surfaces of key components such as pipelines and reverse osmosis membranes, forming biofilms and scale. This not only affects water quality but also increases the operational burden on the equipment and shortens its service life. While killing microorganisms, thermal disinfection also has a certain cleaning effect on the internal scale of the equipment, reducing the accumulation of biofilms and scale and lowering the probability of equipment failures. This extends the replacement cycle of core components such as reverse osmosis membranes, helps ensure the stable operation of the equipment and the continuity of dialysis treatment, and saves maintenance and replacement costs for medical institutions, thereby improving overall operational efficiency.

The thermal disinfection function of modern hemodialysis water treatment equipment is typically highly automated. Through the equipment’s built-in control system, staff only need to simply set parameters such as disinfection time and temperature, and the thermal disinfection program can be automatically initiated. Links such as heating, circulation, and cooling during disinfection require little manual intervention. After disinfection, the equipment can automatically record disinfection data for easy subsequent query and traceability. This characteristic of simple operation and high automation not only reduces the workload of medical staff but also minimizes issues such as incomplete disinfection caused by improper manual operation, aligning with the intelligent and automated development trend of medical equipment.

In the field of hemodialysis water treatment, Kertone has always been driven by innovative technology, continuously deepening technological research and development and product upgrades. It is determined to become a benchmark brand of domestic high-end hemodialysis water machines leading industry development, safeguarding the health of dialysis patients with high-quality and high-performance domestic equipment.

Kertone Smart Hemodialysis Water Treatment Robot excels in integrating advanced thermal disinfection technology. The robot is equipped with both automatic chemical disinfection and thermal disinfection functions. The thermal disinfection system uses a non-contact external heater, where the heating components do not come into contact with water. Temperature and time are automatically calibrated to ensure the stability and reliability of disinfection effects. Meanwhile, when thermal disinfection is activated, electric valves automatically switch, and the thermal disinfection device intelligently controls the water production and shutdown of the water treatment equipment, automatically heating hot water to 85°C and injecting it into the water tank and pipe network, maintaining this temperature for 30 minutes. Additionally, the robot has real-time monitoring and early warning functions. In case of any abnormalities during thermal disinfection, it can promptly issue alarms and take corresponding measures to ensure the safety of equipment and patients.

With these advantages, Kertone Smart Hemodialysis Water Treatment Robot has provided efficient, convenient, and safe hemodialysis water treatment solutions for dialysis centers in many hospitals, gradually becoming a reliable assistant in the industry for ensuring the quality of dialysis water and safeguarding the health of numerous dialysis patients.